Can a Printed Circuit Board Supplier Drive Sustainability?

In today’s rapidly advancing technological landscape, the role of sustainability has become more critical than ever. As industries strive for greener alternatives, a new area of focus is emerging: the environmental impact of the materials and components that make up our electronic devices. One such crucial component is the printed circuit board (PCB), a fundamental part of almost all electronic devices, from smartphones to computers. As the demand for electronics grows, the question arises: Can a printed circuit board supplier drive sustainability? Let’s explore this idea in detail.

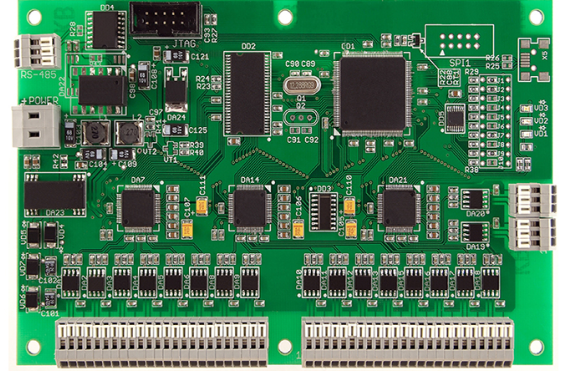

Understanding the Role of Printed Circuit Boards (PCBs)

A Printed Circuit Board (PCB) is an essential part of virtually every electronic device. It acts as the backbone for all electronic components, connecting them via conductive pathways etched into the board. PCBs are typically made from a variety of materials, including copper, plastic, and sometimes, more hazardous substances like lead. As the demand for electronics continues to surge, the environmental implications of PCB production become increasingly important. This raises a vital question for PCB suppliers: can they influence sustainability practices in the production of PCBs?

The Environmental Challenges of PCB Production

The environmental impact of PCB production is multifaceted. First, the materials used to manufacture PCBs, such as copper, aluminum, and rare earth metals, are often mined, a process that can lead to habitat destruction and significant energy consumption. The chemicals used to etch and process these boards can also be harmful to the environment, and improper disposal of waste or outdated devices can lead to toxic leakage into ecosystems.

Another critical environmental challenge is the e-waste problem. As electronic devices reach the end of their life cycle, they often end up in landfills, where the PCBs and other components can leach harmful substances into the soil and water. Furthermore, the short life span of many electronic products, combined with the rapid pace of technological advancements, means that devices are frequently discarded, exacerbating the problem.

The Shift Toward Sustainability in PCB Manufacturing

As awareness of these environmental issues grows, the pressure is on PCB suppliers to adopt more sustainable practices. Sustainability in PCB manufacturing involves several key aspects: reducing environmental impact during production, recycling materials, and ensuring the end-of-life management of PCBs is handled in an environmentally responsible way. Let’s break down how a printed circuit board supplier can make a difference in these areas.

1. Using Eco-Friendly Materials

One of the most significant ways a PCB supplier can drive sustainability is by opting for eco-friendly materials. Traditional PCBs are often made with materials that are harmful to the environment, such as flame retardants, lead, and other toxic chemicals. However, new advances in PCB manufacturing have led to the development of green PCBs, which are made with non-toxic materials and environmentally friendly processes. Suppliers that focus on green PCB production help reduce the environmental footprint of electronics.

For example, lead-free PCBs are becoming more common as an alternative to traditional boards that contain lead, a hazardous substance. The transition to lead-free soldering and other non-toxic alternatives is essential in reducing the harmful effects of electronic waste. Additionally, using materials that are recyclable and biodegradable can further contribute to sustainability efforts in PCB production.

2. Energy-Efficient Manufacturing Processes

In addition to material selection, the production processes used to make PCBs are also a key factor in sustainability. Traditional PCB manufacturing can be energy-intensive, requiring significant electricity and water to process the materials and assemble the boards. Energy-efficient manufacturing methods, such as using renewable energy sources or optimizing production techniques to reduce energy consumption, can help minimize the carbon footprint of PCB production.

A Printed Circuit Board Supplier that invests in energy-efficient technologies not only reduces its environmental impact but also improves its overall operational efficiency. For instance, adopting solar power, wind energy, or other green energy sources can significantly lower the greenhouse gas emissions associated with PCB manufacturing.

3. Recycling and Reuse of Materials

Another critical strategy for PCB suppliers to promote sustainability is through recycling and the reuse of materials. When electronic devices reach the end of their life cycle, recycling the PCBs and other components can recover valuable materials such as copper, gold, and rare earth metals, which can be reused in new products. Suppliers who engage in or partner with recycling programs help close the loop on the lifecycle of electronic components, reducing the need for new raw materials and decreasing the environmental impact.

Additionally, PCB suppliers can ensure that their own manufacturing processes minimize waste by reusing scrap materials whenever possible. For example, by optimizing material usage and minimizing scrap, PCB manufacturers can reduce the overall volume of waste generated, which contributes to more sustainable practices.

4. Designing for Longevity and Repairability

Another sustainable approach that PCB suppliers can adopt is designing products for longevity and repairability. One of the main reasons for e-waste accumulation is the short lifespan of many electronic devices. Many products are not designed for easy repair, resulting in consumers discarding them when a single component fails.

PCB suppliers that focus on designing products that are modular, easy to repair, or upgradeable can help extend the life cycle of electronic devices. For example, designing PCBs that allow for easy replacement of components, or that are compatible with multiple generations of products, can reduce waste and encourage a more sustainable approach to electronics consumption.

The Role of Consumers and Industry Collaboration

While PCB suppliers play a crucial role in driving sustainability, the responsibility does not rest solely with them. Consumers must also play their part by choosing products that are designed with sustainability in mind, recycling old devices, and reducing overall consumption. Furthermore, industry collaboration is essential in creating a more sustainable future. By working together, PCB suppliers, electronics manufacturers, and other stakeholders can develop industry-wide standards for sustainable production and recycling practices.

Conclusion:

The answer is a resounding yes—a Printed Circuit Board Supplier can indeed drive sustainability. By adopting eco-friendly materials, optimizing manufacturing processes for energy efficiency, embracing recycling, and designing for longevity, PCB suppliers can make a significant contribution to the sustainability of the electronics industry. As consumers and industries continue to prioritize sustainability, the demand for green PCBs will only increase, pushing suppliers to innovate and improve their environmental practices.

To Find Out More about how PCB suppliers are embracing sustainability, check over here for case studies and examples of best practices. If you’re looking for sustainable PCB solutions, go right here to find a supplier who shares your commitment to a greener future.

By addressing environmental concerns head-on, PCB suppliers can play a pivotal role in shaping a more sustainable, eco-conscious electronics industry. Their efforts can have a ripple effect, influencing not only the industry but also the wider world as we all work toward a more sustainable future.