Introduction

In today’s industrial landscape, efficient transportation and storage of goods are essential for businesses. One of the most widely used solutions for bulk material handling is the Flexible Intermediate Bulk Container (FIBC), commonly known as bulk bags. FIBC bulk bags are designed to safely and securely transport a variety of products, ranging from agricultural goods to chemicals and construction materials. This comprehensive guide aims to provide a detailed understanding of FIBC bulk bag manufacture, covering various aspects from design and production to their benefits and applications.

FIBC Bulk Bags: An Overview

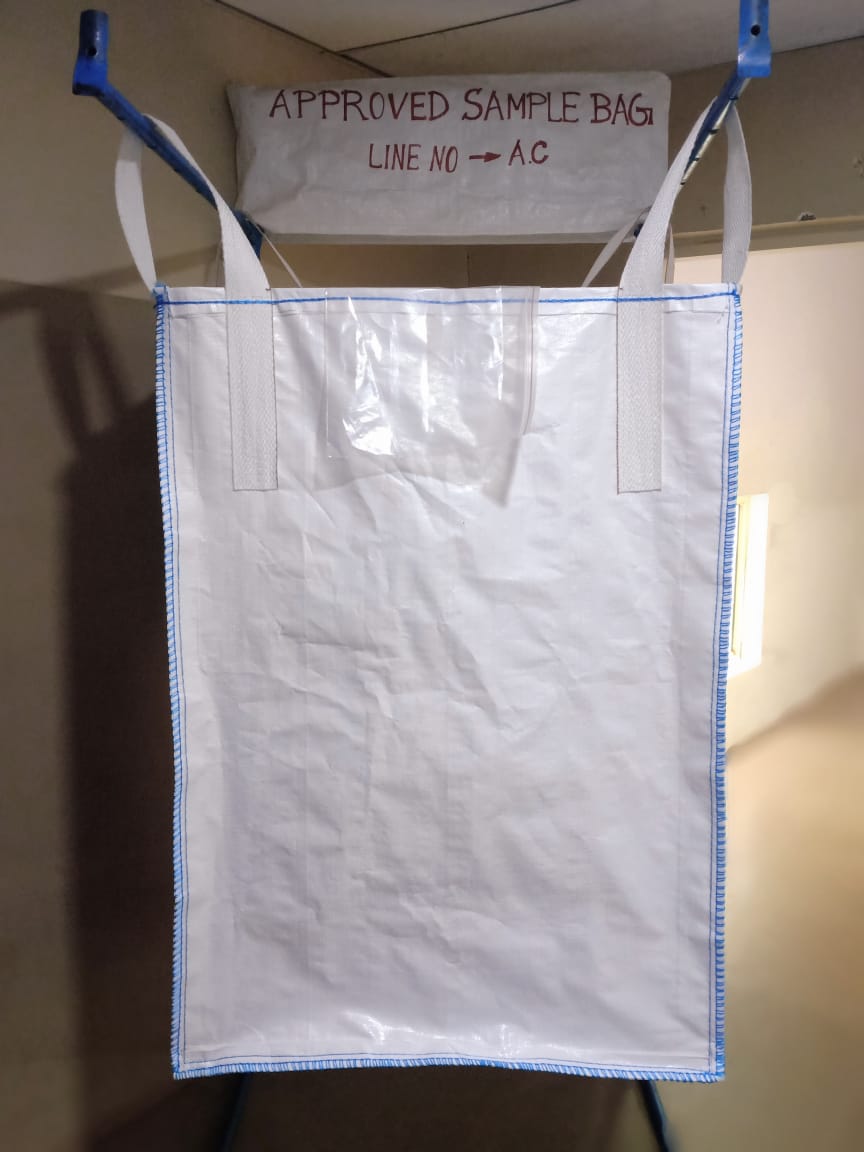

Flexible Intermediate Bulk Containers (FIBCs) are large bags made from flexible and durable woven polypropylene fabric. These bags have the capacity to hold several hundred to several thousand kilograms of bulk materials, such as powders, granules, or flakes. FIBCs are designed to be lifted by forklifts or cranes, making them ideal for transporting and storing a wide range of products in various industries.

FIBC Bulk Bags Manufacture: A Comprehensive Guide to Flexible Intermediate Bulk Containers aims to shed light on the intricacies involved in the production of these versatile bags. Let’s dive deeper into the manufacturing process and explore the different stages involved.

FIBC Bulk Bag Manufacturing Process

- Material Selection and Preparation

The first step in manufacturing FIBC bulk bags is selecting the appropriate raw materials. High-quality polypropylene fabric is commonly used due to its strength, flexibility, and resistance to tearing. The fabric is carefully chosen based on the desired characteristics of the bag, such as weight capacity, UV resistance, or static protection.

Once the fabric is selected, it undergoes a rigorous preparation process, including cleaning and drying. This ensures that the fabric is free from any impurities or moisture that could compromise the bag’s integrity.

- Cutting and Sewing

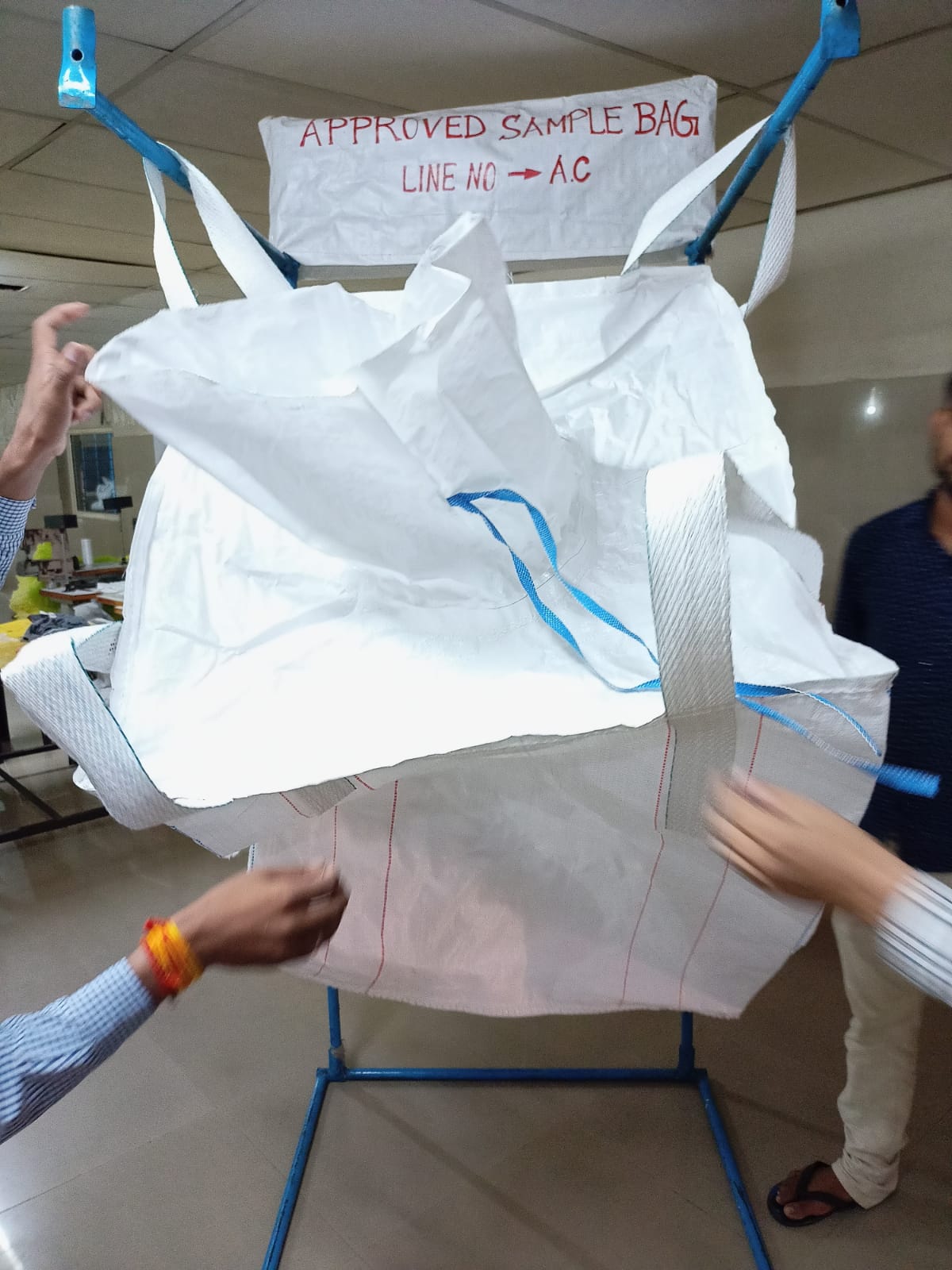

After the fabric preparation, it is time to cut and sew the bag panels. The panels are cut to the desired dimensions using specialized cutting machines. Precision is crucial during this stage to ensure uniformity and consistency in the final product.

The cut panels are then sewn together using high-strength industrial sewing machines. Skilled operators carefully stitch the panels, ensuring tight seams that can withstand the weight and stress exerted on the bag during transportation and storage.

- Adding Reinforcements and Accessories

To enhance the strength and durability of the FIBC bulk bags, reinforcements and accessories are added at specific points. These reinforcements include corner loops, lift loops, and additional layers of fabric in high-stress areas.

Corner loops are typically made from polyester and are designed to facilitate lifting and handling of the bags. Lift loops are attached to the top of the bag and allow for easy loading and unloading. These loops are often color-coded for safety and identification purposes.

- Printing and Labeling

FIBC bulk bags can be customized with printed logos, product information, handling instructions, and safety warnings. This step involves using specialized printing techniques to ensure that the printed information is clear, durable, and resistant to fading or rubbing off.

Labels and tags are also attached to the bags, providing essential details such as weight capacity, dimensions, and safety certifications. This information helps users handle the bags correctly and ensures compliance with industry standards.

- Testing and Quality Control

Before the FIBC bulk bags are ready for use, they undergo a series of tests to ensure their reliability and safety. These tests may include load testing, top lift testing, and fabric strength testing. Qualified inspectors carefully examine each bag, checking for any defects or deviations from the specified standards.

The testing and quality control phase is vital to guarantee that the manufactured FIBC bulk bags meet the required industry regulations and can safely transport and store various types of materials.

Benefits of FIBC Bulk Bags

FIBC bulk bags offer numerous advantages over traditional packaging and transportation methods. Let’s explore some of the key benefits they provide:

Cost-effective: FIBC bulk bags are a cost-effective solution for bulk material handling. They reduce the need for additional packaging materials and streamline logistics, resulting in overall cost savings.

Efficient and Space-saving: These bags are designed to maximize storage and transportation efficiency. Their large capacity allows for more material to be moved in a single trip, reducing handling time and optimizing storage space.

Versatile: FIBC bulk bags can accommodate various types of materials, ranging from fine powders to coarse granules. Their flexibility makes them suitable for industries such as agriculture, chemicals, construction, and mining.

Protection and Safety: The fabric used in FIBC bulk bags provides protection against UV rays, moisture, and contaminants. They can also be equipped with additional features such as anti-static properties or liners for handling hazardous materials.

Eco-friendly: FIBC bulk bags are reusable and recyclable, making them an environmentally friendly choice. By reducing the use of single-use packaging, they contribute to waste reduction and sustainability efforts.

Applications of FIBC Bulk Bags

FIBC bulk bags find application in a wide range of industries and sectors. Some common applications include:

Agriculture: FIBC bulk bags are used for storing and transporting agricultural products such as grains, seeds, fertilizers, and animal feed.

Chemicals: They are utilized for handling and transporting various chemical substances, including powders, pellets, and flakes.

Construction: FIBC bulk bags play a crucial role in the construction industry, where they are used for carrying cement, sand, aggregates, and other construction materials.

Mining: These bags are employed in the mining industry for transporting minerals, ores, and other extracted materials.

Food and Beverages: FIBC bulk bags are suitable for storing and transporting food ingredients, such as sugar, flour, and spices.

FIBC Bulk Bags Manufacture: FAQs

FAQ 1: What are the weight capacities of FIBC bulk bags?

FIBC bulk bags come in a range of weight capacities, depending on their design and intended use. The capacities can vary from as low as 500 kilograms (1100 pounds) to as high as 2000 kilograms (4400 pounds) or more. It is essential to choose the appropriate weight capacity based on the material being transported or stored.

FAQ 2: Can FIBC bulk bags be used for hazardous materials?

Yes, FIBC bulk bags can be specially designed and manufactured to handle hazardous materials. These bags may include additional features like liners, grounding mechanisms, or specialized coatings to ensure safe handling and transportation of hazardous substances.

FAQ 3: Are FIBC bulk bags reusable?

Yes, FIBC bulk bags are reusable, provided they are properly maintained and inspected for damage or wear. Regular inspection and cleaning can extend the lifespan of the bags and contribute to cost savings and sustainability.

FAQ 4: Can FIBC bulk bags be stored outdoors?

FIBC bulk bags can be stored outdoors; however, it is recommended to take precautions to protect them from prolonged exposure to sunlight and harsh weather conditions. UV-resistant fabrics and proper covering can help maintain the bags’ integrity and prolong their lifespan.

FAQ 5: Are FIBC bulk bags recyclable?

Yes, FIBC bulk bags are recyclable. The polypropylene fabric used in their construction can be recycled into various plastic products, reducing the environmental impact and promoting a circular economy.

FAQ 6: What safety certifications should I look for in FIBC bulk bags?

When purchasing FIBC bulk bags, it is essential to ensure they comply with relevant safety standards and certifications. Some common certifications to look for include ISO 21898, UN Dangerous Goods, and AIB Food Grade.

Conclusion

FIBC bulk bags, also known as flexible intermediate bulk containers, offer an efficient, cost-effective, and versatile solution for bulk material handling. This comprehensive guide has provided insights into the manufacture, benefits, and applications of FIBC bulk bags. Understanding the intricacies of their production process and the diverse range of materials they can transport will help businesses make informed decisions when choosing packaging solutions.

With their ability to safely transport and store various products, FIBC bulk bags continue to play a vital role in industries such as agriculture, chemicals, construction, and mining. By optimizing logistics, reducing costs, and promoting sustainability, FIBC bulk bags contribute to the smooth operation of businesses across different sectors.

Reference : -https://www.gettoplists.com/