Importance of Analytical Balances in Pharmaceutical Research

In pharmaceutical research, where even the slightest deviation in measurement can significantly impact drug efficacy and safety, the need for precision is paramount. This is where Analytical Balances play a vital role. These highly sensitive instruments are engineered to deliver accurate mass measurements down to four or five decimal places, making them indispensable in laboratories involved in drug development, formulation, and quality assurance.

This blog explores the importance of analytical balances in pharmaceutical research, their applications, advantages, and how they contribute to ensuring compliance, product quality, and scientific accuracy.

What is an Analytical Balance?

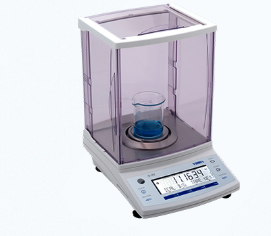

An analytical balance is a high-precision weighing instrument typically used in laboratories for measuring small mass in the sub-milligram range. With readability ranging from 0.1 mg to 0.01 mg (0.0001g), these balances are enclosed in draft shields to eliminate the influence of air currents, vibrations, or dust—factors that could interfere with measurement accuracy.

Because of their incredible sensitivity and reliability, analytical balances are a critical tool in any pharmaceutical lab setting.

Why Analytical Balances Are Crucial in Pharmaceutical Research

1. Accurate Drug Formulation

One of the foundational stages in pharmaceutical research is drug formulation, where the active pharmaceutical ingredient (API) is combined with various excipients to produce a stable, effective, and safe medication. The success of this process heavily depends on the precise measurement of components.

Analytical balances ensure that every milligram of a substance is weighed correctly, preventing errors that could compromise the drug’s performance or shelf life. Inaccurate weighing can lead to dose inconsistency, reduced efficacy, or even adverse effects in patients.

2. Ensuring Consistent Dosage

In the pharmaceutical industry, dosage consistency is vital to maintaining therapeutic effectiveness and avoiding toxicity. Analytical balances help achieve this by enabling scientists to weigh substances with extreme accuracy, ensuring that each unit (tablet, capsule, etc.) contains the exact amount of the drug intended.

This is particularly important for high-potency or narrow therapeutic index drugs, where a minor variation in dosage can lead to severe outcomes.

3. Quality Control and Assurance

Analytical Weighing Balances are heavily used in quality control (QC) laboratories where pharmaceutical products undergo rigorous testing for compliance with standards. From raw materials to the final product, every component is weighed and verified for purity and composition.

Routine use of analytical balances helps detect inconsistencies in:

- API concentrations

- Presence of impurities

- Batch-to-batch variation

This ensures that all products released to the market are safe, effective, and meet regulatory standards such as USP, FDA, or ICH guidelines.

4. Compliance with Regulatory Requirements

Pharmaceutical research and manufacturing are governed by strict regulatory frameworks like Good Laboratory Practice (GLP) and Good Manufacturing Practice (GMP). These regulations emphasize data integrity, traceability, and consistency.

Modern analytical balances come equipped with:

- Built-in calibration systems

- GLP/GMP-compliant printouts

- User access control and audit trails

These features help laboratories maintain data accuracy and regulatory compliance, especially during audits and inspections.

5. Critical Role in Research and Development (R&D)

Pharmaceutical R&D labs depend on analytical balances for:

- Weighing raw materials for chemical synthesis

- Measuring solvents and reagents for reactions

- Analyzing compounds for preclinical studies

A minor variation in weight can skew experimental results or cause unintended chemical reactions. Thus, repeatability and accuracy are essential to ensure that research findings are valid, reproducible, and reliable.

6. Micro-Dosing and Controlled Substances

Modern therapies increasingly involve micro-dosing—administering medications in microgram quantities to minimize side effects or increase efficacy. Analytical balances enable researchers to measure these ultra-small quantities accurately.

Additionally, pharmaceutical research involving controlled substances demands high levels of precision to stay within legal limits and maintain documentation. Analytical balances help maintain this control effectively.

Key Features of Analytical Balances for Pharma Labs

To meet the high standards of pharmaceutical applications, analytical balances offer features such as:

- High readability (up to 0.00001 g) for minute measurements

- Internal automatic calibration to ensure consistent accuracy

- Antistatic technology to reduce weighing errors

- Touchscreen interfaces for easy operation

- Enclosed draft shields to protect from environmental disturbances

- Data connectivity for easy recordkeeping and compliance tracking

These features allow researchers and technicians to maximize productivity while ensuring measurement integrity.

Best Practices for Using Analytical Balances in Pharma Labs

To maintain the accuracy and longevity of analytical balances, the following best practices are recommended:

1. Proper Placement

- Keep the balance on a vibration-free, level surface.

- Place it away from direct sunlight, doors, windows, or air vents.

2. Daily Calibration

- Perform internal or external calibration regularly, especially before important measurements.

- Use certified calibration weights suitable for your balance’s range.

3. Regular Cleaning

- Clean the weighing chamber and pan daily using a soft brush and lint-free cloth.

- Avoid spillage and contamination by using appropriate weigh boats or containers.

4. Controlled Environment

- Maintain a consistent room temperature and humidity level.

- Eliminate static electricity by grounding the device if necessary.

5. Training and Documentation

- Ensure all lab personnel are trained on proper balance usage.

- Maintain logbooks for calibration, maintenance, and servicing.

Future Trends: Smarter Balances for Smarter Labs

With advancements in laboratory automation, analytical balances are becoming smarter and more integrated with lab information management systems (LIMS). Features like:

- Cloud connectivity

- Real-time data syncing

- AI-driven performance diagnostics

…are transforming pharmaceutical labs into more data-driven and efficient environments, where human error is minimized and compliance is easier to maintain.

The importance of analytical balances in pharmaceutical research cannot be overstated. These instruments form the backbone of any pharmaceutical lab by ensuring precision, reliability, and compliance in every step—from drug formulation to quality control.

By investing in high-quality analytical balances and adhering to best practices, pharmaceutical organizations can safeguard their data integrity, accelerate research timelines, and ensure that their products are safe and effective for public use.

In a world where accuracy can save lives, analytical balances are not just instruments—they are essential partners in pharmaceutical innovation.