Crafting Excellence: SAMACH’s Cutting-Edge Innovations in Woodworking Machine and Edge Banding Machine Technology

In the ever-evolving world of woodworking, innovation is essential—and few names stand as tall as SAMACH, a company at the forefront of intelligent furniture production machinery. Offering a full suite of solutions—from CNC routers to sanding machines—the company sets the industry standard for performance and reliability. Among its standout offerings are the Woodworking Machine series and, more specifically, the Edge Banding Machine, each playing a pivotal role in modern manufacturing.

A Legacy of Precision: SAMACH’s Woodworking Machine Lineup

SAMACH has built its reputation on delivering equipment that blends power with precision, automation with ease of use. The Woodworking Machine category spans an impressive range of toolsets suitable for panel processing, solid wood work, drilling, boring, and beyond. Their portfolio includes:

- Panel Saw: Engineered for precise cuts in wood-based panels, these machines support high-volume production lines.

- Drilling & Boring Machine: They deliver pinpoint accuracy in pocketing and dowel insertion, essential for modular furniture.

- CNC Router: A versatile tool for shaping, carving, and contour cutting.

- Membrane Press Machine, Painting Machine, Sanding Machine: These complete the production chain with finishing touches and surface perfection.

By combining these capabilities, SAMACH solidifies its status as a one-stop provider for end-to-end furniture manufacturing. Whether you’re processing MDF, plywood, or solid wood, their Woodworking Machine suite meets every need.

Why SAMACH’s Edge Banding Machine Stands Apart

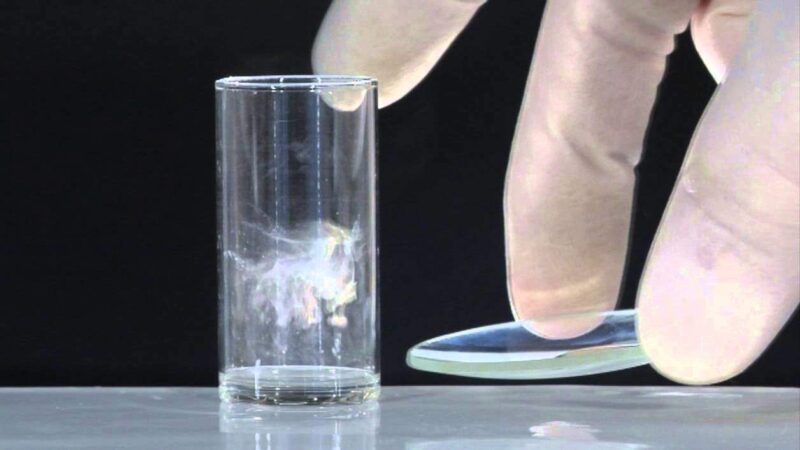

Among the robust equipment lineup, the Edge Banding Machine deserves special attention for its role in final assembly. Edge banding involves applying a narrow strip of material—often PVC, ABS, wood veneer, or melamine—to seal and enhance the edges of panels.

SAMACH’s Edge Banding Machine shines due to:

- Exceptional Finish Quality – It ensures seamless bonding and trimming, ideal for visible edges on cabinetry, furniture components, and architectural panels.

- Flexibility in Materials – Operators can work with various edge profiles and materials to suit aesthetics and durability requirements.

- Automated Precision – From glue application to edge trimming and end-cutting, the machine reduces manual interventions and human error.

- High Throughput – Capable of handling continuous production runs, it empowers manufacturers to scale with consistency and speed.

- User-Friendly Operation – SAMACH designs its machinery with intuitive controls and maintenance simplicity in mind.

By integrating the Edge Banding Machine into a broader Woodworking Machine system, manufacturers unlock comprehensive, efficient, and fully automated production workflows.

BENEFITS OF INTEGRATING THE EDGE BANDING MACHINE INTO THE WOODWORKING CHAIN

Taking a holistic approach, here’s how SAMACH helps optimize your production flow:

- Streamlined Workflow: Combine panel cutting, edge sealing, finishing, and sanding into a unified process—minimizing material handling and transition delays.

- Consistent Quality: Automation across all Woodworking Machine stages ensures uniform part quality from start to finish.

- Reduced Labor Costs: Smart machines cut down on manual labor—letting operators focus on oversight rather than repetitive tasks.

- Minimal Downtime: Built for durability, SAMACH machinery requires little maintenance and keeps production lines running smoothly.

- Adaptable Systems: As design trends evolve, so do materials and edge finishes—SAMACH’s flexible Edge Banding Machine lets you adapt swiftly.

A Day in the Factory: Practical Workflow Example

- Material Preparation: Raw panels enter the line for cutting with the Panel Saw, then move to the Drilling & Boring Machine for hinges, dowels, or lock fittings.

- Routing and Profiling: The CNC Router crafts curved shapes, decorative profiles, or mortises, depending on the furniture design.

- Edge Sealing: The Edge Banding Machine takes center stage—applying adhesive, trimming edges, and rounding them for professional appeal.

- Finishing Touches: The Sanding Machine prepares the surface for painting or veneering, while the Painting Machine adds protective paint or UV coatings.

- Final Assembly: Optional machines like the Membrane Press Machine adhere films or laminates, finalizing the product before shipping.

This integrated flow highlights how SAMACH’s Woodworking Machine ecosystem—with the Edge Banding Machine as a key component—delivers both speed and precision.

Why Manufacturers Choose SAMACH

- Global Support and Expertise

With export experience and training services, SAMACH supports clients in installing and optimizing their Woodworking Machine setups. - High Stability and Durability

Their machines are built to withstand demanding production environments, reducing downtime and maintenance needs. - Building the Future of Furniture

As intelligent furniture becomes more complex in form and function, SAMACH’s innovations help furniture makers stay ahead with adaptable tools like the Edge Banding Machine.

Industry Trends & SAMACH’s Forward-Looking Innovation

- Customization Demand

End users increasingly expect personalized furniture—SAMACH’s systems, bolstered by Edge Banding Machine flexibility, cater to this need. - Lean Manufacturing

The trend toward lean operations is embraced via automation of key woodworking steps—from trimming to finishing—ensuring a high-efficiency assembly line. - Sustainable Materials

As eco-friendly board materials and eco-compatible edges gain popularity, SAMACH’s versatile Woodworking Machine and Edge Banding Machine can accommodate new substrates and adhesives. - Smart Factory Integration

With Industry 4.0 on the rise, SAMACH continuously upgrades its controls and sensor systems to enable real-time monitoring and predictive maintenance.

Sustainability and Efficiency: SAMACH’s Dual Commitment

SAMACH’s engineering doesn’t just prioritize production—it aligns with sustainability ideals. Efficient glue usage, reduced material waste, and energy-saving drive units all bolster eco-conscious manufacturing. The Edge Banding Machine, in particular, minimizes adhesive excess with precision application, cutting waste and post-process cleanup.

Maintenance & Support: Keeping Your Edge Sharp

A robust Woodworking Machine system is only as good as its upkeep. SAMACH supports comprehensive maintenance plans—covering training, spare parts, and remote diagnostics—to ensure that your Edge Banding Machine and other tools remain consistently productive.

Testimonials from Leading Manufacturers

- “SAMACH’s integrated line, especially the Edge Banding Machine, doubled our output with better edge quality.” — a modern furniture producer

- “We switched to SAMACH for reliability; their Edge Banding Machine ensures flawless finishes every day.” — custom cabinetry maker

These voices reflect the tangible impact of combining quality Woodworking Machine assets with cutting-edge edge banding tools.

Conclusion: The SMART Future of Woodworking with SAMACH

In today’s fast-paced furniture industry, delivering high-quality products with minimal waste and maximum efficiency is non-negotiable. SAMACH delivers on all fronts—with a complete Woodworking Machine lineup and a standout Edge Banding Machine that ensures performance, adaptability, and an elegant finish.

Choose SAMACH, and you’re not just investing in machinery—you’re securing an intelligent, sustainable, and future-ready manufacturing partner.