Shrink Film Wrapping Machines for Small Businesses: Affordable Options and Best Practices

In today’s competitive market, small businesses need efficient and cost-effective packaging solutions to enhance product presentation and ensure safe transportation. A shrink film wrapping machine is an excellent investment for businesses looking to streamline their packaging process while maintaining a professional look. With various options available, choosing the right machine that fits a small business’s budget and requirements can be challenging. This blog explores affordable options for shrink film wrapping machines and best practices to maximize their benefits.

Understanding Shrink Film Wrapping Machines

Shrink film wrapping machines use heat to shrink a plastic film tightly around products, providing a secure and tamper-evident seal. These machines are commonly used in industries such as food and beverage, retail, pharmaceuticals, and manufacturing. The shrink-wrapping process not only enhances the visual appeal of products but also protects them from dust, moisture, and damage during transit.

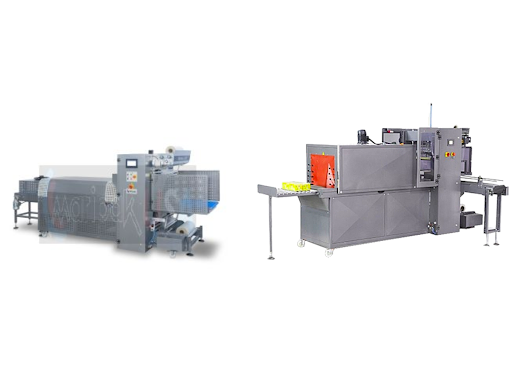

Small businesses can choose from different types of shrink film wrapping machines based on their packaging volume and budget. The primary types include:

- Manual Shrink Wrapping Machines: These are cost-effective and suitable for businesses with low production volumes.

- Semi-Automatic Shrink Wrapping Machines: These machines offer a balance between affordability and efficiency, reducing labor costs while maintaining control over packaging operations.

- Automatic Shrink Packaging Machines: These high-speed machines are designed for businesses with higher packaging demands, offering seamless and efficient wrapping with minimal manual intervention.

Affordable Options for Small Businesses

Investing in the right shrink film wrapping machine is crucial for small businesses aiming to optimize their packaging process without overspending. Here are some affordable options:

1. Manual Shrink Wrapping Machines

For small-scale operations, manual shrink wrapping machines provide a cost-effective solution. These machines typically consist of a sealing bar and a heat gun or shrink tunnel to apply heat to the film. While they require more labor, they are an excellent choice for businesses with limited packaging needs.

2. Tabletop Semi-Automatic Shrink Wrappers

Tabletop shrink wrappers are compact and cost-effective, making them ideal for small businesses operating from limited spaces. They offer faster sealing and shrinking capabilities than manual machines while still being budget-friendly.

3. Entry-Level Automatic Shrink Packaging Machines

Small businesses with growing production demands can consider entry-level automatic shrink packaging machines. These machines reduce labor costs and improve efficiency without requiring a significant investment. Many manufacturers offer compact automatic models specifically designed for small businesses.

4. Used or Refurbished Machines

For businesses with tight budgets, purchasing a used or refurbished shrink film wrapping machine can be a viable option. Many reputable suppliers offer well-maintained second-hand machines at a fraction of the cost of new ones.

Best Practices for Using Shrink Film Wrapping Machines

To maximize the benefits of a shrink film wrapping machine, small businesses should follow best practices for operation and maintenance:

1. Choose the Right Shrink Film

Selecting the appropriate shrink film is essential for achieving optimal results. Common options include:

- Polyolefin (POF) Shrink Film: Offers superior clarity and durability, making it ideal for retail products.

- Polyvinyl Chloride (PVC) Shrink Film: Cost-effective but less durable, suitable for lightweight packaging.

- Polyethylene (PE) Shrink Film: Used for heavy-duty bundling applications.

2. Optimize Machine Settings

Properly configuring temperature, sealing time, and conveyor speed (if applicable) ensures high-quality shrink wrapping. Experimenting with different settings helps find the optimal combination for specific products.

3. Regular Maintenance

Routine maintenance prevents unexpected breakdowns and extends the lifespan of the machine. Key maintenance tasks include:

- Cleaning the sealing bar and shrink tunnel to remove film residues.

- Checking heating elements for wear and tear.

- Lubricating moving parts as recommended by the manufacturer.

4. Train Employees Properly

Providing proper training for employees ensures efficient machine operation and minimizes errors. Operators should understand how to load film, adjust settings, and troubleshoot minor issues.

5. Monitor Packaging Quality

Regularly inspecting wrapped products helps identify any issues such as wrinkles, weak seals, or excessive film usage. Adjusting settings accordingly improves the overall packaging quality.

Conclusion

Shrink film wrapping machines offer an excellent packaging solution for small businesses, providing protection, efficiency, and professional presentation. Whether opting for a manual, semi-automatic, or automatic shrink packaging machine, businesses should assess their needs and budget before making a decision. By following best practices, including selecting the right shrink film, optimizing machine settings, and maintaining equipment, businesses can maximize their investment. For those needing high-volume bundling, shrink film bundling equipment may be a worthwhile addition to their packaging setup.