How to Improve Efficiency of Water Treatment Process Equipment with SS Chemical Pump

Clean and safe water is very important for our homes, farms, and factories. To make dirty water clean, we use special machines called Water Treatment Process Equipment. These machines help remove dirt and harmful things from water so we can use it safely.

But for these machines to work well, they need the right parts. One important part is called the SS Chemical Pump. This pump helps move and mix chemicals that clean the water.

In this article, we will explain how this pump can help the water cleaning machines work better. Don’t worry — we will use very simple words so everyone, even kids, can understand easily.

What Is Water Treatment Process Equipment?

Water Treatment Process Equipment means the machines and tools that help clean dirty water. They remove harmful things like chemicals, germs, and mud from the water. These machines include filters, tanks, pipes, and pumps.

One important pump is called an SS Chemical Pump. It helps in adding and moving cleaning chemicals into the water.

The main goal of this equipment is to make water clean and safe to use in homes, farms, and factories.

Understanding the Role of SS Chemical Pump

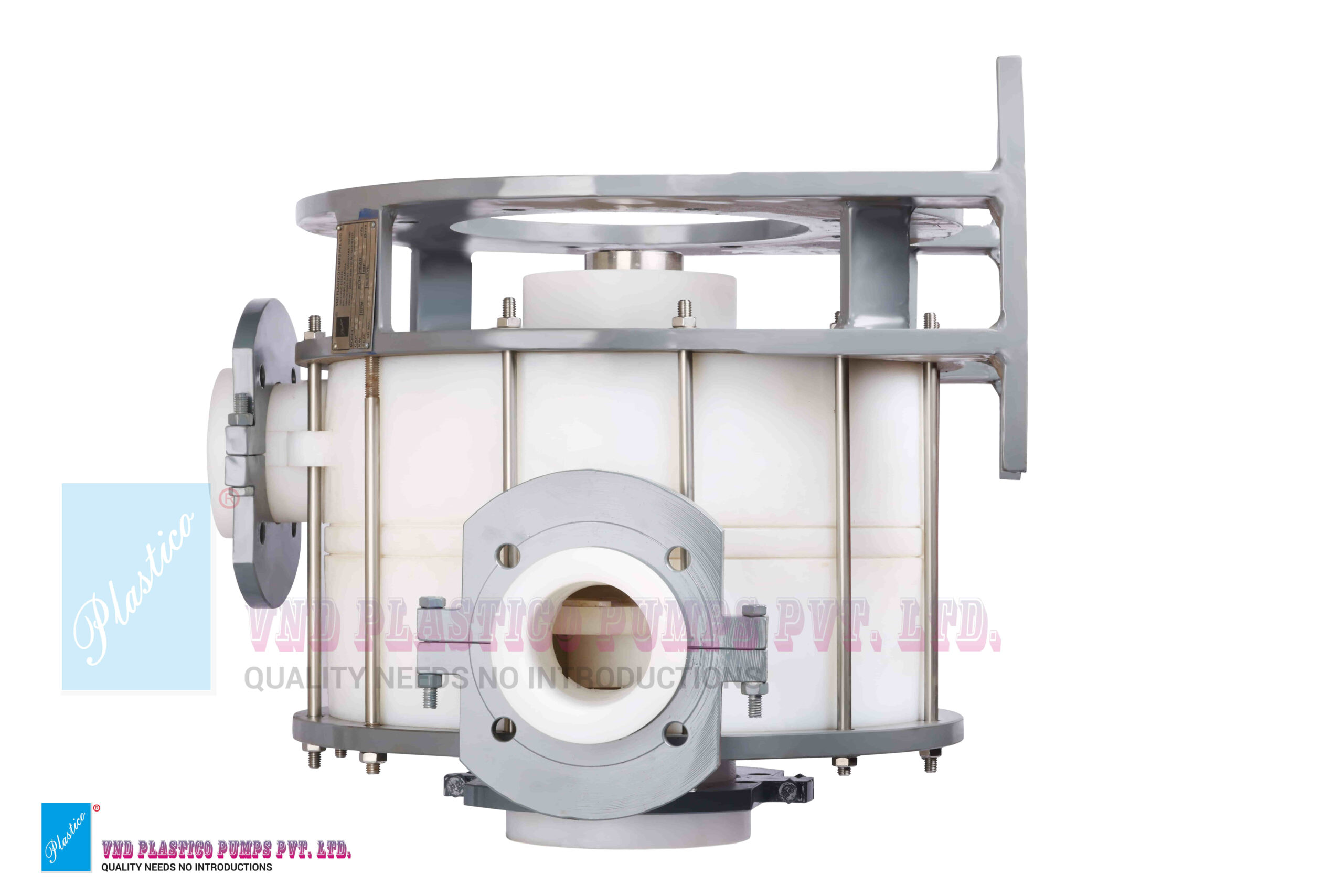

An SS Chemical Pump is made of stainless steel (SS) and is designed to handle corrosive and hazardous liquids like acids, alkalis, and other chemicals. In a Water Treatment Process Equipment setup, these pumps are crucial for:

- Dosing chemicals like chlorine, alum, or coagulants

- Circulating fluids within the system

- Maintaining proper pressure and flow during treatment

- Transferring waste or by-products safely

Because of its corrosion-resistant properties, an SS Chemical Pump ensures durability and long-term performance in water treatment systems.

Why Efficiency Matters in Water Treatment?

Efficiency in Water Treatment Process Equipment means:

- Saving energy and reducing electricity costs

- Reducing downtime and maintenance

- Ensuring consistent water quality

- Enhancing the lifespan of the system

When equipment runs more efficiently, it not only performs better but also saves operational costs and time.

How to Boost Efficiency Using SS Chemical Pump

1. Choose the Right Size and Capacity

Every water cleaning machine setup needs different things. That’s why it’s important to choose the right size of SS Chemical Pump and how fast it moves the water.

If the pump is too big or too small, it can waste energy or not clean the water properly. So, picking the right one is very important.

2. Ensure Proper Material Compatibility

The chemicals used in water treatment can be highly corrosive. An SS Chemical Pump made from stainless steel resists corrosion, ensuring safe and long-lasting operation. This improves the reliability and reduces wear and tear on your Water Treatment Process Equipment.

3. Regular Maintenance and Inspection

Machines don’t work well if they are not taken care of. To keep your SS Chemical Pump working properly, check it often for leaks, strange sounds, or if it’s not working like before.

Clean the filters, check the rubber seals, and get it serviced on time. This will help the machine stay strong and do its job well.

4. Monitor Flow and Pressure

You can use sensors and smart machines to check how fast water is moving and how much pressure it has. An SS Chemical Pump with a special part called a VFD (Variable Frequency Drive) can change its speed depending on what is needed. This helps save energy and makes the water cleaning process work better.

5. Integrate Automation Systems

Today’s water cleaning machines use digital controls and smart systems. These can work together with SS Chemical Pumps to add the right amount of cleaning chemicals, reduce waste, and keep the water clean all the time — without needing someone to do it by hand.

Benefits of Using SS Chemical Pump in Water Treatment

- Corrosion resistance ensures longer life

- Low maintenance reduces operational costs

- Smooth chemical transfer enhances treatment results

- High efficiency means lower energy bills

- Safe handling of hazardous chemicals

These advantages make SS Chemical Pump a smart investment for anyone looking to improve their Water Treatment Process Equipment.

Common Mistakes to Avoid

- Using the wrong pump type for chemical compatibility

- Ignoring regular maintenance

- Operating at incorrect pressure or speed

- Skipping calibration of dosing systems

Avoiding these errors will help maintain the efficiency of your system and extend its lifespan.

Conclusion

Improving how water treatment machines work isn’t just about buying big or expensive machines — it’s also about using the right parts, like an SS Chemical Pump. This pump helps move and mix chemicals safely and easily during the water cleaning process.

If you choose a good SS Chemical Pump and take care of it, your machines will work better, break down less, and cost less to run. Whether it’s a city water plant or a private system, using strong and trusted parts makes a big difference.

VND Plastico Pumps has strong and smart SS Chemical Pumps made to fit perfectly with your water treatment machines.